If you have any questions, please contact our online customer service staff immediately

Click:375Edit: 375Edit: Global

Click:375Edit: 375Edit: Global Time:2026-01-09 15:42:52

Time:2026-01-09 15:42:52

In industrial lifting, few tools match the electric chain hoist for consistent reliability, operational efficiency, and robust performance. Far more than a simple lifting device, it represents a critical fusion of mechanical engineering and electrical control, designed to handle repetitive, demanding workloads with precision and safety.

Core Engineering & Operational Superiority

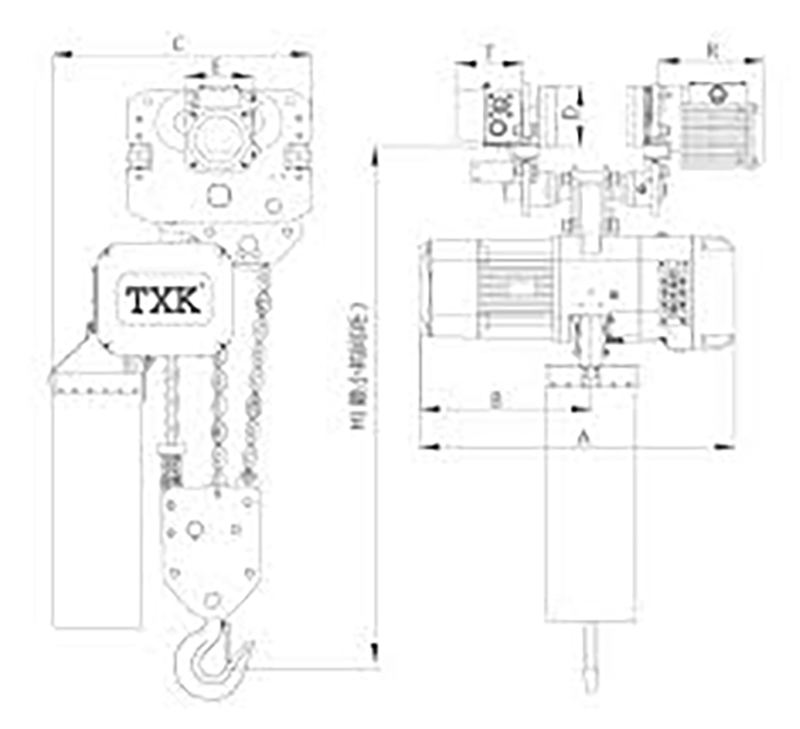

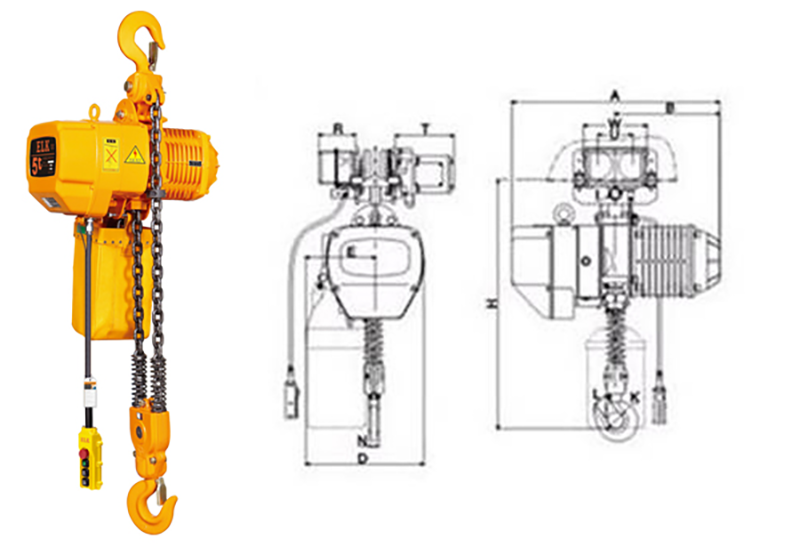

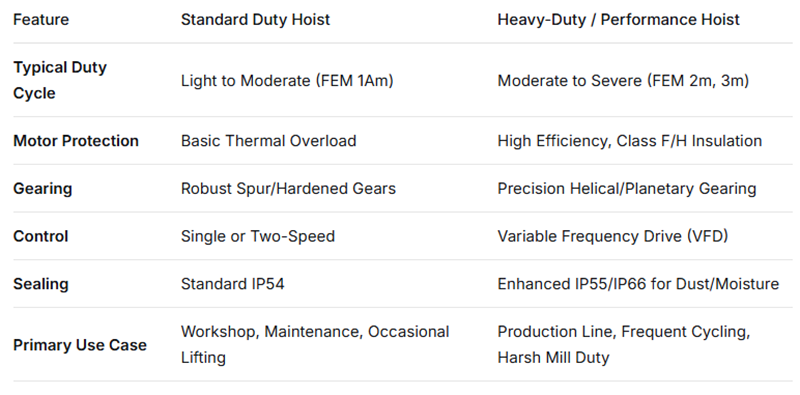

The modern electric chain hoist is defined by its optimized drive system. A high-torque, thermally protected electric motor works in concert with a multi-stage helical or planetary gear train. This combination provides controlled power transmission, ensuring smooth acceleration and deceleration while minimizing gear wear. The result is precise load control—essential for accurate positioning of machinery, delicate assemblies, or valuable materials.

Load chains are typically made from alloy steel, heat-treated for a balance of tensile strength and flexibility. Their design allows for a compact reeving system, giving the hoist a low headroom—a crucial advantage in facilities with limited overhead space. Compared to wire rope, the chain is more resistant to damage from kinking or crushing and is easier to inspect for wear.

The Critical Role of the Braking System

Safety is engineered into the hoist’s core through its braking systems. The primary mechanical load brake is fail-safe, automatically engaging to hold the load if power is lost. Many models incorporate an additional motor brake for faster stopping and precise inching control. For operators, this creates a fundamental confidence: the load is secure, enhancing safety and productivity during alignment or assembly tasks.

Application-Specific Configurations

The true value of an electric chain hoist is realized in its application. In machine shops and fabrication plants, they enable the safe installation and removal of heavy tooling. On assembly lines, they facilitate the ergonomic positioning of components, reducing worker strain. In warehouse settings, they are integral to material handling systems, often paired with push or motorized trolleys for horizontal movement along I-beam tracks.

Harsh environments demand specialized engineering. Hoists rated for foundries or outdoor use feature enclosed motors, upgraded seals, and corrosion-resistant coatings or stainless-steel components to withstand heat, moisture, and particulate contamination.

Technical Selection: Beyond Basic Capacity

Selecting the right hoist requires a deep analysis of operational parameters:

Duty Cycle & Motor Class:Intermittent use differs vastly from continuous operation. The motor's insulation class and duty rating (e.g., FEM 1Am, 2m) must align with the actual work frequency to prevent overheating.

Lifting Speed & Control:Standard single-speed hoists suit general purpose work. For precise final positioning, variable frequency drive control offers infinitely adjustable speeds and exceptionally smooth operation.

Lifting Height & Voltage: Ensure adequate chain capacity for the full lift. Verify the supply voltage matches your facility’s power system.

Safety & Compliance: Key features include a certified overload limiter, low-voltage (24V) control circuits, and emergency stop functions. Compliance with regional standards (ASME, EN, ISO) is non-negotiable for liability and safety.

Comparative Technical Overview

The Strategic Advantage: Total Cost of Ownership

While the initial investment is a consideration, the total cost of ownership is dominated by reliability and service life. A professionally specified hoist reduces costly downtime from failures, minimizes energy consumption through efficient gearing and motors, and extends service intervals. Its durability under load ensures asset integrity over decades, not just years.

Conclusion: Engineered for Dependability

An electric chain hoist is a fundamental component of industrial infrastructure. Its value lies not in novelty, but in proven, disciplined engineering that delivers predictable performance under load. By prioritizing precision gear systems, failsafe braking, and a configuration matched to your specific environmental and operational demands, you invest in more than a tool—you secure a foundational element for safe, efficient, and continuous production.

Evaluate your application demands with precision. Our engineering team provides technical consultation to specify the exact hoist system your operation requires.

In 2026, safety will remain a top priority for businesses operating material handling equipment. According to the British Safety Council, approximately 1,300 people are involved in forklift-related accidents each year, several of which are fatal. Failure to maintain a safe working environment can result in serious legal consequences for both companies and their directors. As a result, there is growing recognition that forklifts must deliver maximum value in terms of safety.

2026-01-28View More →

Safety certification has become a critical consideration in the lifting equipment industry. Regulatory requirements are becoming stricter worldwide, and end users are increasingly aware of the risks associated with uncertified products.

2026-01-20View More →

In industrial lifting, few tools match the electric chain hoist for consistent reliability, operational efficiency, and robust performance. Far more than a simple lifting device, it represents a critical fusion of mechanical engineering and electrical control, designed to handle repetitive, demanding workloads with precision and safety.

2026-01-09View More →