If you have any questions, please contact our online customer service staff immediately

Click:503Edit: 503Edit: Admin

Click:503Edit: 503Edit: Admin Time:2025-12-10 16:28:59

Time:2025-12-10 16:28:59

As global manufacturing, logistics, and infrastructure development continue to expand, the lifting equipment industry is entering a new growth cycle in 2025. From construction and factories to ports and warehousing, safe and efficient lifting tools are becoming essential for companies aiming to enhance productivity and operational safety.

To help industry users understand the shifting landscape, we present a detailed overview of the key trends driving the global lifting equipment market in 2025.

Products such as electric hoists, electric winches, wire rope hoists, chain slings, and lifting beams are seeing the fastest increase in global demand.

The focus of lifting equipment development is shifting rapidly from basic functionality to intelligent, safer, and more efficient solutions.

Electrification Becomes Mainstream√ More precise safety control

These technologies are transitioning from optional add-ons to standard configurations.

Customers are increasingly favoring suppliers that provide full documentation, quality traceability, and strict testing reports.

These products are growing faster because they offer lower cost, simple installation, and wide usability.

Manufacturers with independent production capability + engineering expertise + global after-sales support are becoming the preferred partners.

The global market is expected to reach a new peak by 2027.

In 2026, safety will remain a top priority for businesses operating material handling equipment. According to the British Safety Council, approximately 1,300 people are involved in forklift-related accidents each year, several of which are fatal. Failure to maintain a safe working environment can result in serious legal consequences for both companies and their directors. As a result, there is growing recognition that forklifts must deliver maximum value in terms of safety.

2026-01-28View More →

Safety certification has become a critical consideration in the lifting equipment industry. Regulatory requirements are becoming stricter worldwide, and end users are increasingly aware of the risks associated with uncertified products.

2026-01-20View More →

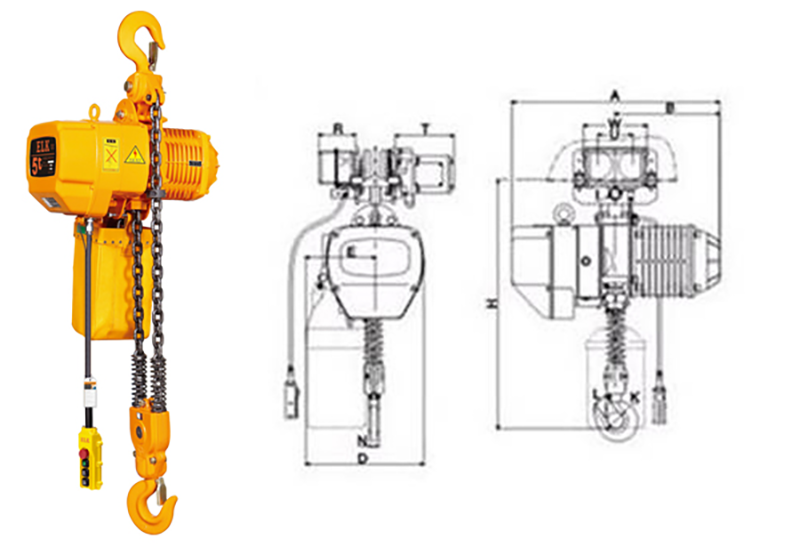

In industrial lifting, few tools match the electric chain hoist for consistent reliability, operational efficiency, and robust performance. Far more than a simple lifting device, it represents a critical fusion of mechanical engineering and electrical control, designed to handle repetitive, demanding workloads with precision and safety.

2026-01-09View More →