If you have any questions, please contact our online customer service staff immediately

Click:379Edit: 379Edit: Admin

Click:379Edit: 379Edit: Admin Time:2025-12-25 17:12:46

Time:2025-12-25 17:12:46

Material handling is not something most companies plan to spend time thinking about. It’s just part of the job. Boxes arrive, pallets move, parts go from one station to another. It happens all day, every day — and usually nobody notices it until something goes wrong.

A worker gets hurt. A shipment is delayed. A machine breaks down at the worst possible moment. Then suddenly material handling becomes a “problem”.

One of the most common issues is still cost. Large equipment is expensive to buy, expensive to maintain, and often more than what a facility actually needs. Many warehouses don’t need a full forklift fleet or a complex automated system. They need something simpler, something that fits the space, the volume, and the people they have.

Safety is another point that’s hard to ignore. Anyone who has spent time on a warehouse floor has seen how easy it is for someone to lift the wrong way, rush a job, or try to handle a load that is just a bit too heavy. These small decisions add up. Over time they lead to back injuries, strained shoulders, and people being out of work longer than expected.

Then there is the question of speed. Not “how fast can we go at full capacity”, but how smoothly work flows on a normal day. When workers walk back and forth too much, when loads are handled twice instead of once, or when people wait for equipment to become available, time is lost quietly, minute by minute.

In 2026, safety will remain a top priority for businesses operating material handling equipment. According to the British Safety Council, approximately 1,300 people are involved in forklift-related accidents each year, several of which are fatal. Failure to maintain a safe working environment can result in serious legal consequences for both companies and their directors. As a result, there is growing recognition that forklifts must deliver maximum value in terms of safety.

2026-01-28View More →

Safety certification has become a critical consideration in the lifting equipment industry. Regulatory requirements are becoming stricter worldwide, and end users are increasingly aware of the risks associated with uncertified products.

2026-01-20View More →

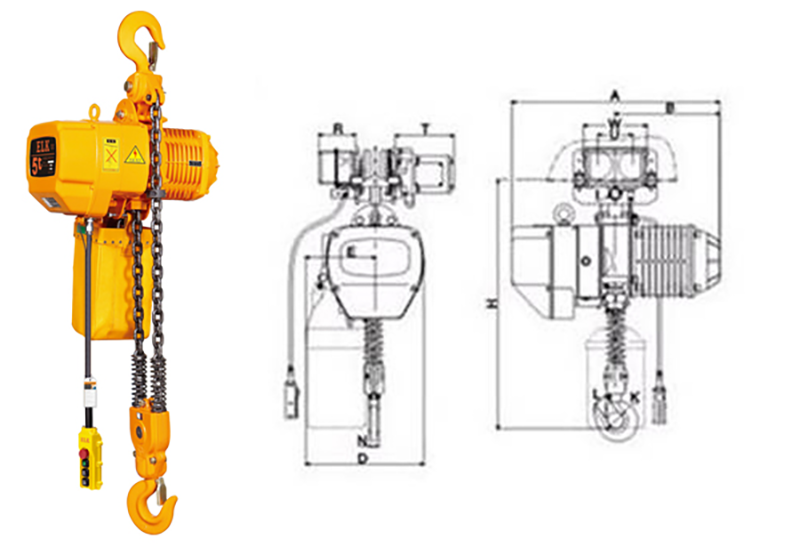

In industrial lifting, few tools match the electric chain hoist for consistent reliability, operational efficiency, and robust performance. Far more than a simple lifting device, it represents a critical fusion of mechanical engineering and electrical control, designed to handle repetitive, demanding workloads with precision and safety.

2026-01-09View More →